How Does the Manufacturing Process for Plastic Parts Differ from Metal Parts in Aeronautics and Medical Applications?

The manufacturing process for plastic parts differs significantly from metal parts in aeronautics and medical applications due to variations in material properties, processing techniques, and quality requirements.

Material selection: While metal parts predominantly use alloys like aluminum, titanium, or stainless steel, plastic parts utilize various types of polymers such as polypropylene, polyethylene, polycarbonate, or polyamide. Material selection for plastic parts considers factors like mechanical properties, chemical resistance, biocompatibility (in medical applications), and cost-effectiveness.

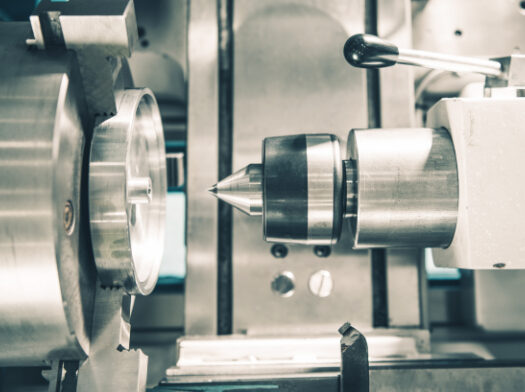

Processing techniques: Metal parts are typically manufactured through processes like machining, forging, or casting. In contrast, plastic parts are commonly produced through techniques like injection molding, blow molding, or extrusion. Injection molding, the most prevalent method, involves injecting molten plastic into a mold cavity and allowing it to solidify. This enables the production of complex shapes with high precision and efficiency.

Design considerations: Plastic parts often require different design considerations than metal parts. Plastic parts may require thicker walls, ribs, or reinforcing features to compensate for lower strength and rigidity compared to metals. Additionally, considerations for mold design and tooling are crucial in plastic part manufacturing, ensuring proper flow, cooling, and ejection of the molten plastic.

Quality control: Quality control measures for plastic parts focus on factors such as dimensional accuracy, surface finish, and material consistency. Non-destructive testing methods used in metal part manufacturing, like X-ray or ultrasonic inspections, may not be applicable to plastic parts. Instead, visual inspection, dimensional measurement, and material testing techniques specific to plastics are employed to ensure quality and reliability.

In summary, the manufacturing process for plastic parts in aeronautics and medical applications differs from that of metal parts in terms of material selection, processing techniques, design considerations, and quality control. Understanding these differences is crucial for producing high-quality plastic parts that meet the unique requirements of these industries.