Plastic Injection Molding

Revolutionizing Modern Manufacturing

For Your Information

Plastic injection molding is a transformative manufacturing process that has revolutionized the production of plastic parts and components. It is a versatile and cost-effective method widely used across various industries, from automotive and electronics to medical devices and consumer goods.

We at Vaness Manufacturing do not produce plastics injection molding. For your education, in this article, we delve into the world of plastic injection molding, exploring its key principles, applications, advantages, and the impact it has had on modern manufacturing.

Understanding Plastic Injection Molding

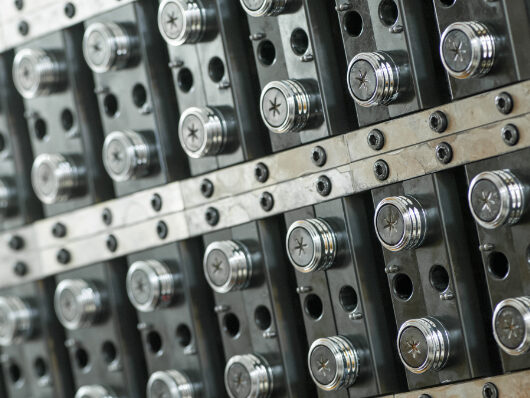

In this section, we provide an in-depth explanation of the plastic injection molding process. We explore the essential components of an injection molding machine, such as the injection unit, mold clamping unit, and ejection system. We also discuss the key steps in the process, from material selection and preparation to the injection and cooling of the plastic material.

Versatility and Applications

Plastic injection molding offers unparalleled versatility, allowing the production of intricate and complex parts with high precision. This article highlights the diverse applications of plastic injection molding across industries, including automotive parts, electronic enclosures, medical devices, household appliances, and more. We also examine how the process caters to both large-scale production and custom-made components.

Materials and Material Selection

The success of plastic injection molding heavily relies on the choice of materials. This section explores the different types of plastics used in the process, such as thermoplastics and thermosetting plastics. We discuss the properties and characteristics of various plastic materials and the importance of material selection based on specific project requirements.

Advantages of Plastic Injection Molding

Plastic injection molding offers a myriad of advantages that make it a preferred manufacturing method. This article delves into the benefits of injection molding, including high production efficiency, repeatability, low labor costs, minimal material wastage, and the ability to produce complex geometries and intricate features.

Design Considerations for Plastic Injection Molding

Effective design is a critical aspect of successful plastic injection molding. In this section, we explore design considerations, such as draft angles, wall thickness, parting lines, and gating design. We discuss how design optimization ensures efficient and cost-effective manufacturing processes.

Sustainability in Plastic Injection Molding

In recent years, sustainability has become a significant concern in the manufacturing industry. This article examines the efforts of plastic injection molding companies to embrace sustainable practices, such as using recycled materials, reducing energy consumption, and employing environmentally-friendly molding techniques.

Challenges and Future Trends

While plastic injection molding offers numerous advantages, it also faces certain challenges. This section delves into common challenges, such as material selection for specific applications, maintaining consistent part quality, and addressing environmental concerns. We also discuss emerging trends and technologies that are shaping the future of plastic injection molding, including advancements in automation, 3D printing, and material innovations.

Conclusion

Plastic injection molding has transformed the way we manufacture plastic components, enabling efficient, precise, and cost-effective production across diverse industries. Its versatility, sustainability efforts, and ability to drive innovation make it a cornerstone of modern manufacturing. As technology continues to advance, plastic injection molding will continue to play a pivotal role in shaping the future of manufacturing and product development.