Key Considerations

When manufacturing metal parts for aeronautics and medical applications, several key considerations must be taken into account to ensure the highest standards of quality, safety, and reliability. These considerations encompass material selection, precision manufacturing processes, regulatory compliance, and stringent quality control measures.

Material selection plays a crucial role in metal part manufacturing. Aerospace and medical industries often require materials with exceptional mechanical properties, such as high strength, durability, and corrosion resistance. Aluminum alloys, titanium alloys, stainless steel, and nickel-based alloys are commonly used due to their favorable characteristics and compatibility with industry requirements.

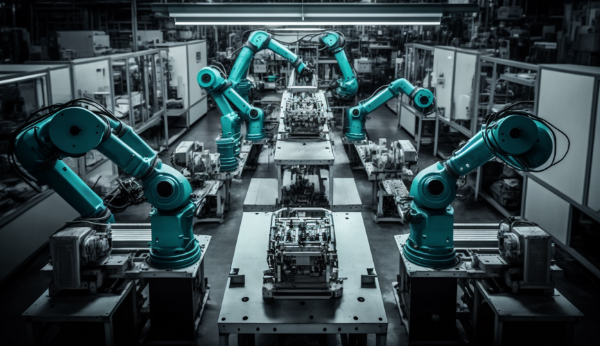

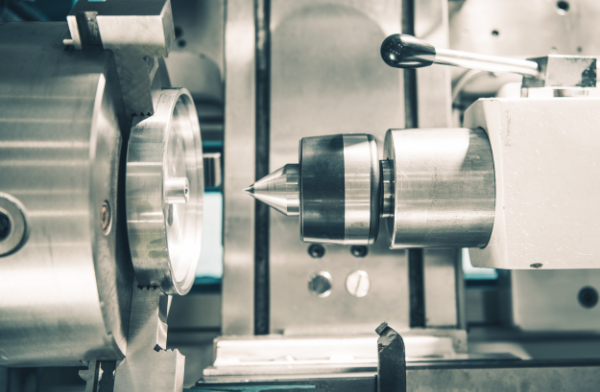

Precision manufacturing processes are paramount in these industries to achieve tight tolerances and precise dimensions. Advanced techniques like CNC machining, laser cutting, and additive manufacturing (3D printing) are employed to ensure the desired level of accuracy and repeatability in metal part production.

Regulatory compliance is another critical consideration, particularly in medical applications. Compliance with regulations such as ISO 13485 for medical devices and various aviation authorities’ standards, like FAA or EASA regulations, is necessary to ensure the safety and efficacy of the manufactured parts. Strict documentation, traceability, and adherence to industry-specific quality management systems are essential.

Quality control measures are implemented throughout the manufacturing process to identify and eliminate defects. Non-destructive testing (NDT) methods such as X-ray inspection, ultrasound testing, and visual inspections are employed to detect flaws or inconsistencies in the metal parts. Additionally, rigorous testing and validation procedures are conducted to ensure the parts meet the required specifications and standards.

Overall, the key considerations when manufacturing metal parts for aeronautics and medical applications revolve around material selection, precision manufacturing processes, regulatory compliance, and robust quality control measures. By addressing these considerations effectively, manufacturers can meet the stringent demands of these industries and deliver reliable, high-quality metal parts that meet the needs of aeronautics and medical applications.