CNC Machining Services:

Precision Engineering for the Modern World

For Your Information

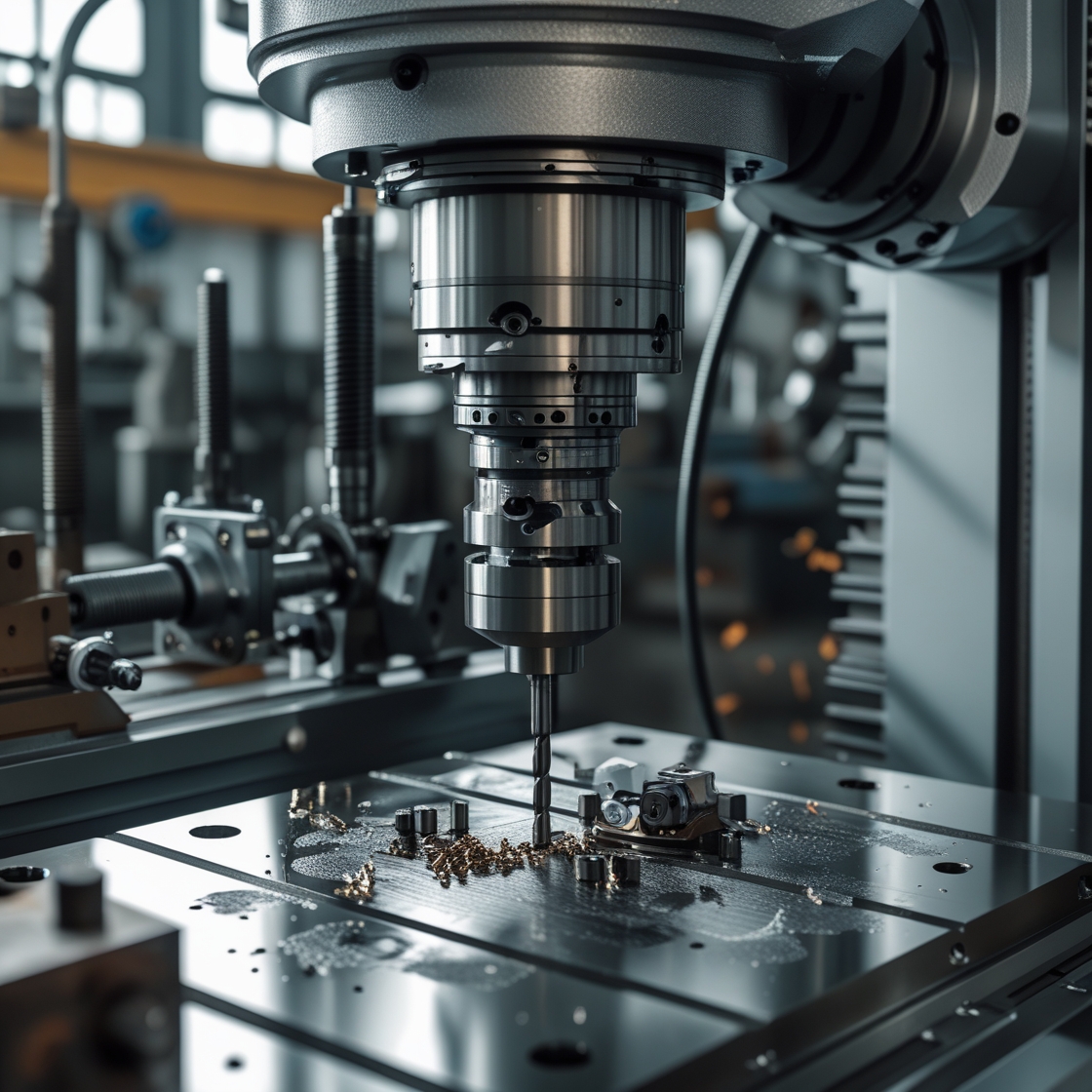

CNC machining services have emerged as a fundamental pillar of modern manufacturing, providing a wide range of industries with the ability to create intricate and high-quality components with exceptional precision. Computer Numerical Control (CNC) technology has revolutionized the way we design and manufacture parts, offering a level of accuracy and efficiency that was once unimaginable. In this article, we explore the world of CNC machining services, the key principles behind this technology, its diverse applications, and the advantages it brings to the manufacturing landscape.

Understanding CNC Machining Services

In this section, we provide an in-depth explanation of CNC machining services, covering the basic principles of CNC technology, its components, and how it works. We explore the role of CAD/CAM software in converting designs into precise machine instructions, the importance of choosing the right cutting tools, and the types of CNC machines used in various applications.

Versatility and Applications

One of the primary strengths of CNC machining services is their incredible versatility. This article highlights the vast range of industries that benefit from CNC machining, including aerospace, automotive, electronics, medical, and more. We delve into the diverse applications, from producing complex engine components to crafting intricate electronic circuit boards, and how CNC machining has enabled the creation of cutting-edge products.

Precision Engineering for Quality Components

Precision is the cornerstone of CNC machining services. This section explores how CNC machines deliver unrivaled accuracy, repeatability, and consistency, leading to the creation of high-quality components with tight tolerances. We discuss the importance of dimensional accuracy and surface finish in meeting stringent industry standards and customer demands.

Materials and Material Selection

CNC machining services can work with a wide array of materials, from metals like aluminum, steel, and titanium to various plastics and composite materials. This article examines the factors that influence material selection, such as the specific application, mechanical properties required, and cost considerations. We also discuss how advanced CNC machines can handle tough materials with ease.

Advantages of CNC Machining Services

CNC machining services offer numerous advantages that set them apart from traditional machining methods. This section delves into the benefits of CNC machining, including reduced lead times, improved production efficiency, lower labor costs, minimized waste, and the ability to produce complex geometries and intricate features.

Customization and Prototyping

CNC machining services are well-suited for custom projects and prototyping. We explore how CNC machines can quickly produce prototypes for design validation and product testing, enabling iterative design improvements. This section also discusses the role of CNC machining in meeting unique client requirements and delivering tailor-made solutions.

Trends and Future of CNC Machining Services

As technology evolves, CNC machining services continue to push the boundaries of innovation. This article examines emerging trends, such as multi-axis machining, automation, lights-out manufacturing, and the integration of AI and machine learning in optimizing CNC processes.

Conclusion

CNC machining services have transformed the landscape of modern manufacturing, enabling industries to achieve levels of precision, efficiency, and customization that were once unimaginable. As the demand for high-quality components continues to grow, CNC machining services will remain at the forefront of innovation, driving advancements in various sectors and shaping the future of manufacturing.